A coilgun, sometimes referred to as a Gauss rifle, is a type of electromagnetic launcher (EML) that functions as a linear motor to accelerate a projectile to high velocities. It is a system designed to convert stored electrical energy directly into the kinetic energy of a projectile. The fundamental architecture of a coilgun consists of one or more stationary solenoid coils, known as stators, which are arranged sequentially along a non-magnetic barrel. When energized, these coils generate a powerful magnetic field that exerts a force on a projectile, or armature, positioned within the barrel, propelling it forward along the common axis. The core components of a coilgun system include the stator coil assembly, the projectile, a high-power energy storage unit, and a sophisticated switching and control system. The coils are typically wound from conductive wire and mounted on a guide tube, while the projectile can be either a ferromagnetic material attracted by the magnetic field or a conductive material repelled by induced currents. This contactless method of acceleration is a defining characteristic of the coilgun.

The coilgun is one of two principal EML concepts, the other being the railgun. While both are designed to achieve high velocities using electromagnetic principles, their mechanisms of operation are fundamentally different. A railgun accelerates a conductive projectile or a sliding armature by passing an extremely high current. This armature completes a circuit between two parallel conductive rails, and the interaction between the current in the armature and the magnetic field generated by the rails produces a powerful Lorentz force that drives the projectile forward. This process necessitates direct, high-pressure sliding electrical contact between the armature and the rails, which leads to significant frictional and resistive heating, rapid barrel erosion, and the formation of a plasma arc at the muzzle.

In contrast, the coilgun's operation is entirely inductive. Magnetic fields accelerate the projectile without any physical or electrical contact with the barrel or coils. This contactless nature eliminates the primary sources of wear and degradation found in railguns, theoretically allowing for longer barrel life and higher repetition rates. Furthermore, because coilguns are multi-turn devices, they can possess considerably higher inductance than railguns, which can be advantageous for matching with certain types of pulsed power supplies. Coilguns also avoid the use of chemical propellants, which are often expensive, toxic, or unstable to store. The silent, smokeless operation of a coilgun provides a distinct advantage in applications where low observability is a requirement.

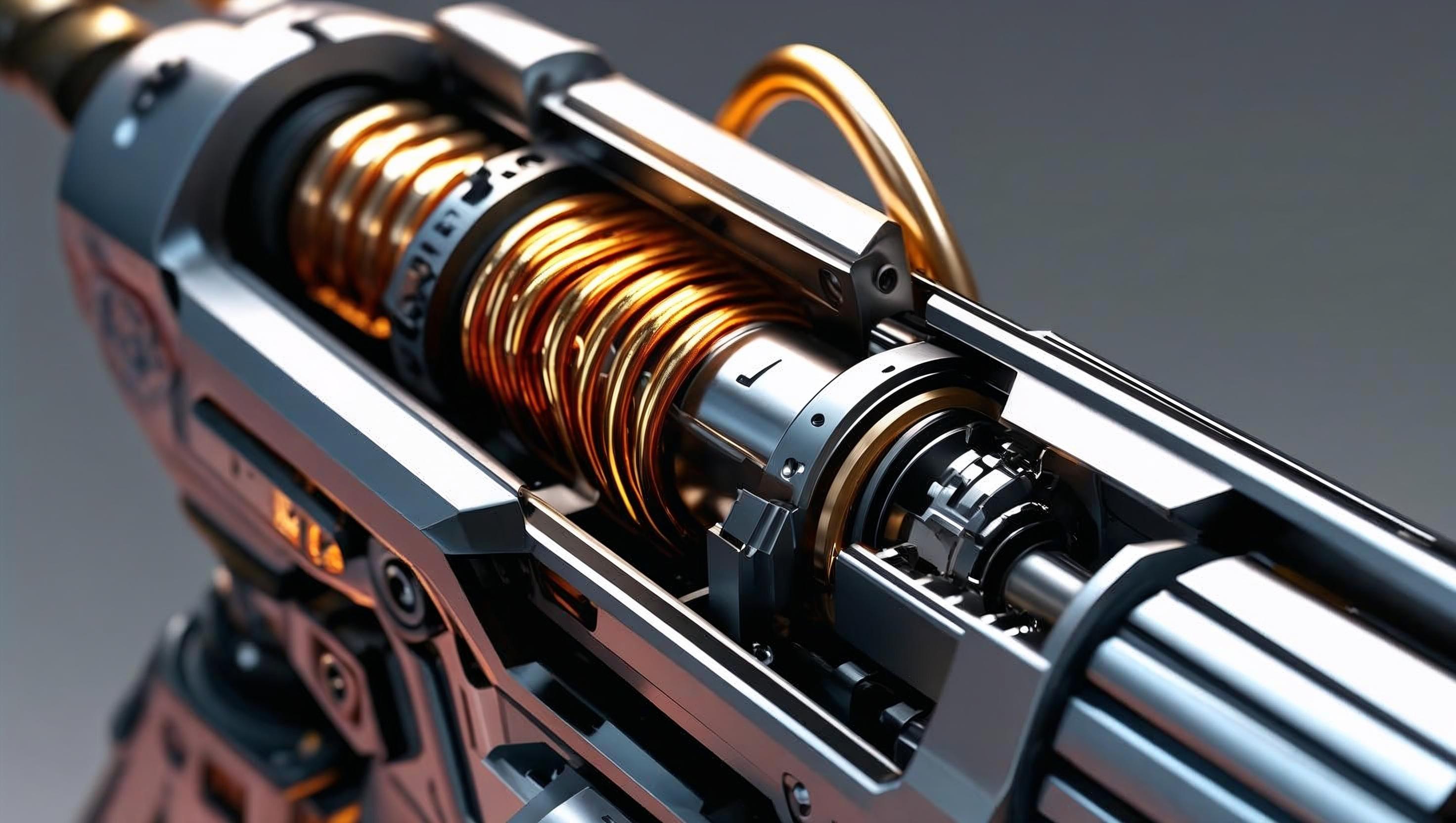

An İmage Depicting a Gauss Gun (Generated by Artificial İntelligence)

Historical Context and Motivation

The concept of using electromagnetic forces for projectile propulsion is over a century old. The first operational coilgun was developed and patented by Norwegian scientist Kristian Birkeland in 1904. Later, in 1933, American inventor Virgil Rigsby developed a stationary coilgun intended for use as a machine gun, powered by a large motor and generator. Despite these early efforts, the technology remained largely conceptual due to the limitations of available electrical components, particularly in energy storage and high-speed switching.

Significant progress in the field began in the latter half of the 20th century, spurred by advancements in pulsed power technology. Research institutions, notably Sandia National Laboratories, have been instrumental in advancing coilgun design since the 1970s, developing and testing launchers capable of accelerating projectiles ranging from several grams to multiple kilograms to velocities exceeding 1 km/s.

This sustained research interest is driven by the potential for coilguns to overcome the fundamental limitations of conventional chemical-propellant guns. Chemical launchers are ultimately limited by the expansion speed of the propellant gases, a constraint that makes achieving hypervelocities (velocities significantly exceeding the speed of sound) inefficient and impractical. Electromagnetic launchers, by contrast, are not bound by this sonic limit. This makes them a compelling technology for a wide range of future applications, including advanced military ordnance, cost-effective space launch systems for delivering payloads to orbit, and specialized scientific instruments for fundamental physics research.

However, the history of coilgun development is marked by a persistent dichotomy between its theoretical promise and its practical implementation. From the earliest concepts to modern research, the advantages of contactless acceleration, controllable thrust, and stealth have been clear. Yet, these benefits have always been counterbalanced by significant engineering challenges, most notably low energy conversion efficiency, the complexity of power conditioning, and the stringent requirements for precise timing control. While the technology of individual components like capacitors and solid-state switches has improved dramatically, the fundamental physics of converting stored electrical energy into projectile kinetic energy within a pulsed inductive system remains the central and most difficult challenge to overcome. The evolution of the field is therefore not a simple story of increasing power, but a nuanced and ongoing effort to bridge the gap between compelling theory and efficient, reliable hardware.

Theoretical Foundations and Modeling

Principles of Electromagnetic Acceleration

The propulsive force in a coilgun is generated by creating a strong magnetic field gradient along the axis of the barrel. A projectile placed within this gradient experiences a force that accelerates it toward the region of higher field intensity. The magnitude of this force is directly proportional to the product of the current flowing through the coil and the spatial rate of change (the gradient) of the mutual inductance between the stator coil and the projectile. This fundamental principle can be realized through two primary mechanisms: reluctance acceleration and induction acceleration.

Reluctance Acceleration

Reluctance acceleration is the conceptually simpler of the two methods. It employs a projectile made of a ferromagnetic material, such as iron or mild steel, which has a high magnetic permeability and thus a low magnetic reluctance. When a strong current pulse is passed through the stator coil, it generates an intense magnetic field. This field magnetizes the projectile and exerts an attractive force, pulling the low-reluctance object toward the point of maximum magnetic flux density, which is typically located at the center of the coil. The projectile is thereby accelerated from its initial position into and through the coil. The force is purely attractive, and its effectiveness depends on creating a steep gradient in the magnetic field for the projectile to follow.

Induction acceleration, also known as repulsive or asynchronous acceleration, utilizes a projectile or an armature made of a highly conductive but non-ferromagnetic material, such as an aluminum cylinder or sleeve. According to Faraday's law of induction, the rapidly changing magnetic field produced by the pulsed current in the stator coil induces circulating electrical currents, known as eddy currents, within the conductive projectile. Lenz's law dictates that these induced currents flow in a direction that creates a magnetic field opposing the change in the stator's field. The interaction between the stator's primary magnetic field and the projectile's opposing secondary magnetic field results in a strong repulsive Lorentz force. This force pushes the projectile away from the stator coil, accelerating it down the barrel. This method relies on transient electromagnetic effects and the principles of mutual inductance and magnetic diffusion.

Mathematical Modeling of Coilgun Dynamics

The launching process in a coilgun is a complex, transient electromagnetic phenomenon. To analyze and optimize coilgun designs without resorting to expensive and time-consuming prototyping, sophisticated mathematical models are employed. These models range from simplified circuit-based approaches to comprehensive multi-physics simulations.

The evolution of these modeling techniques has mirrored the increasing complexity of the hardware itself. For early, single-stage designs, the system could be reasonably approximated using analytical equations derived from basic RLC circuit theory. However, as research progressed toward multi-stage systems capable of achieving higher velocities, the problem transformed into one of multiple, electromagnetically coupled circuits. This coupling, where the mutual inductance between coils and the projectile is a dynamic function of the projectile's position, rendered purely analytical solutions intractable. This necessitated a shift toward numerical methods, where the system is described by a set of simultaneous, nonlinear ordinary differential equations solved using algorithms like the fourth-order Runge-Kutta method.

The accuracy of these circuit-based models depends on having precise values for the lumped parameters, such as the self and mutual inductances and their spatial gradients. To obtain these parameters, especially for complex geometries, engineers turned to Finite Element Method (FEM) analysis. FEM solvers can accurately calculate the magnetic field distribution within the launcher, from which the necessary inductance and force profiles can be extracted and fed into the system-level circuit model. This hybrid field-circuit approach combines the detailed physical accuracy of FEM with the computational efficiency of a circuit simulation.

As performance demands pushed coilguns into hypervelocity regimes, new physical phenomena that were previously negligible became critical. At extreme energy levels, armatures can experience significant Joule heating, leading to melting, and the immense magnetic pressures can cause mechanical deformation. These effects alter the projectile's electrical and geometric properties during the launch, invalidating the assumptions of rigid bodies and constant resistance used in earlier models. Specialized simulation codes, such as the SLINGSHOT code developed at Sandia National Laboratories, were created to handle these complexities. However, even these advanced lumped-parameter codes have limitations. The need to model phenomena like armature melting, the use of novel pulsed power sources, and the inclusion of permeable materials for magnetic shielding experiments has driven the development of a new generation of multi-physics simulation tools. These next-generation codes are designed to fully couple the electromagnetic, thermal, and structural mechanics domains, providing a high-fidelity simulation capability that is essential for designing the next wave of high-performance coilguns. This co-evolution of hardware ambition and simulation capability demonstrates that progress in the field is intrinsically linked; advances in physical launchers create new computational challenges, and new simulation tools enable the design of more advanced hardware.

System Architecture and Component Design

The practical realization of a coilgun, whether a single-stage demonstrator or a complex multi-stage accelerator, requires the careful design and integration of several key subsystems. The performance of the overall system is highly dependent on the characteristics of its components, including the stator coil assembly, the projectile, the pulsed power system, and the timing and control electronics.

Stator Coil Assembly

The stator assembly is the heart of the coilgun, responsible for generating the magnetic fields that drive the projectile. It consists of one or more solenoidal coils mounted sequentially on a barrel.

- Construction: The coils are typically wound from insulated copper wire around a non-magnetic and electrically non-conductive guide tube. Materials like polycarbonate, styrene, or acrylic are often used for the barrel to ensure that it does not interfere with the magnetic fields or create unwanted eddy currents. The windings are often secured with epoxy or other structural adhesives to withstand the strong repulsive forces generated during firing.

- Geometry: The geometry of the coils is a critical design parameter. The length, inner and outer diameters, number of turns, and number of layers all influence the coil's inductance, resistance, and the resulting magnetic field strength and shape. The ratio of the coil's length to the projectile's length is a key factor that must be optimized to achieve efficient energy transfer.

- Multi-stage Configuration: While a single coil can accelerate a projectile, achieving high muzzle velocities requires a multi-stage configuration. In this design, multiple coils are placed in series along the barrel. Each coil, or "stage," is energized in a precisely timed sequence to provide an additional acceleration pulse as the projectile travels past it. In some advanced designs, the length of successive stages may increase to accommodate the increasing velocity of the projectile, ensuring that the duration of the force application remains optimal.

Projectile (Armature) Design

The projectile, or armature, is the component that is accelerated by the magnetic forces. Its design is intrinsically linked to the type of coilgun and its intended performance.

- Material: The choice of projectile material depends on the acceleration principle being used. Reluctance coilguns require a ferromagnetic projectile to be attracted by the magnetic field. Induction coilguns, conversely, require a highly conductive, non-ferromagnetic armature, such as an aluminum sleeve, in which repulsive eddy currents can be induced. More recent and advanced research has explored the use of high-strength permanent magnets, such as sintered Neodymium magnets, as projectiles. The intrinsic magnetic field of a permanent magnet can interact more strongly with the stator field, offering a path to significantly improved performance.

- Design Trade-offs: The design of the armature involves a critical trade-off between its electrical properties, its mass, and its structural integrity. For instance, a more massive armature has a greater thermal capacity to absorb resistive heat generated by eddy currents, but its inertia also lowers the overall payload efficiency of the system. The structural design must be robust enough to withstand the immense compressive magnetic forces during launch without deforming.

Pulsed Power and Switching Systems

The pulsed power system is responsible for storing and delivering the immense bursts of electrical energy required to energize the stator coils.

- Energy Storage: The standard method for energy storage in coilguns is a bank of high-energy capacitors. Capacitors are ideal for this application because they can be charged over seconds and then discharged almost instantaneously, delivering extremely high peak currents (hundreds or thousands of amperes) in a timeframe of milliseconds or microseconds. In multi-stage systems, each coil is often powered by its own dedicated capacitor bank to allow for independent control.

- High-Speed Switching: The ability to switch these high currents precisely and rapidly is arguably the most critical technological challenge in coilgun design. Several types of high-power semiconductor switches are used:

- Silicon Controlled Rectifiers (SCRs): These are robust devices capable of handling very high currents and are often used in high-power coilgun demonstrators.

- Insulated-Gate Bipolar Transistors (IGBTs) and MOSFETs: These switches offer excellent high-speed performance and are common in smaller-scale or more precisely controlled systems.

- Relays: While simple mechanical relays are sometimes used in hobbyist designs, their slow switching times (on the order of 10 milliseconds) make them unsuitable for high-performance coilguns. The significant delay would cause the trigger signal to lag far behind a fast-moving projectile. Solid-state relays (SSRs) offer a much faster alternative, with sub-millisecond switching speeds that are better suited for the application.

- Protective Circuitry: When the current to an inductive coil is abruptly switched off, the collapsing magnetic field can induce a large voltage spike (inductive kickback) that can destroy the switching components. To prevent this, a flyback diode is typically placed in parallel with the coil to provide a safe path for the current to dissipate.

Control and Timing Subsystems

The performance of a multi-stage coilgun is less limited by the power of any individual stage and more by the precision and speed of its control system. While building a single-stage coilgun is a relatively straightforward exercise in power electronics, scaling up to a high-performance multi-stage system introduces a formidable control challenge that dominates the design complexity. Firing a coil at the wrong moment can not only fail to accelerate the projectile but can actively decelerate it, catastrophically degrading performance.

This requirement for perfect synchronization necessitates a closed-loop control system composed of sensors, a processor, and switches.

- Projectile Sensing: To trigger each coil at the optimal moment, the system must track the projectile's position in real-time. This is commonly achieved using optical sensors. Infrared (IR) emitter-detector pairs or photogates are placed along the barrel to detect when the projectile breaks a beam of light. The signals from these sensors provide precise position and velocity data.

- Control Logic: The sensor data is fed to a microcontroller (e.g., an Arduino-based controller), which acts as the brain of the system. The microcontroller executes a control algorithm to calculate the exact moment to fire the next coil based on the projectile's measured position and velocity. It then sends a trigger signal to the corresponding high-speed switch. The difficulty of this task is compounded by the projectile's extreme speed. For a projectile traveling at 100 feet per second, a seemingly minor 10-millisecond delay in a mechanical relay corresponds to one foot of travel, making such components useless without complex and often unreliable predictive timing algorithms. This forces the adoption of faster and more expensive solid-state components.

Ultimately, the engineering focus for advanced multi-stage coilguns shifts from raw power electronics to high-speed instrumentation and real-time control. The success of such a design becomes a software and systems integration challenge as much as a hardware one. The "nervous system" of the coilgun—its ability to sense, process, and act in microseconds—is what determines its viability as a high-performance accelerator.

Performance Analysis, Limitations, and Optimization

The performance of a coilgun is typically evaluated based on two primary metrics: the final muzzle velocity of the projectile and the overall system efficiency. Historically, a major limitation of coilgun technology has been its low efficiency in converting stored electrical energy into projectile kinetic energy. A significant portion of the research in this field is therefore dedicated to understanding performance limitations and developing strategies to overcome them.

Efficiency and Energy Conversion

Coilgun efficiency is defined as the ratio of the projectile's kinetic energy to the initial electrical energy stored in the power supply, usually a capacitor bank. Experimental systems commonly report efficiencies in the low single digits, often between 0.3% and 5%. The primary reason for this low efficiency is energy loss through several mechanisms. A significant portion of the energy is dissipated as heat due to the electrical resistance of the coil windings (Joule heating). Additional energy is lost to resistive heating from eddy currents induced in the projectile and support structures. Finally, imperfect magnetic coupling between the stator coils and the projectile means that not all of the magnetic field energy generated by the coils contributes to the propulsive force.

While typical efficiencies are low, some highly optimized research prototypes and large-scale theoretical designs have demonstrated the potential for much better performance. Documented experimental efficiencies have reached levels of 4.7% and 6.7% through careful design. Large-scale simulations for space launch applications have even predicted overall efficiencies as high as 45%, although achieving such performance in practice remains a formidable challenge.

The "Suck-Back" Effect

A critical performance-limiting phenomenon, particularly in reluctance-type coilguns, is the "suck-back" effect. This occurs when the current pulse in a stator coil remains active after the projectile has passed the point of maximum magnetic attraction (the coil's center). As the projectile moves away from the center, the still-active magnetic field exerts an attractive force in the reverse direction, pulling the projectile backward and actively decelerating it. This can severely reduce or even negate the velocity gained in that stage.

To mitigate the suck-back effect, the timing of the current pulse is paramount. The control system must ensure that the current is "quenched," or switched off, at the precise moment the projectile reaches the center of the coil. As projectile velocities increase, the window of time for this switching action becomes progressively smaller, making the timing control increasingly difficult and critical to the launcher's success.

Advanced Optimization Strategies

The most significant advances in coilgun performance have come not from simply increasing the input power, but from intelligently shaping the electromagnetic interaction in both space and time. This represents a paradigm shift in design philosophy, from a brute-force approach of "more power" to a more nuanced strategy of creating "smarter fields." This evolution in thinking can be seen in several key optimization techniques.

- Non-Uniform Coil Windings: Early designs often used simple, uniformly wound solenoids. However, the magnetic field inside a long, uniform solenoid is nearly constant, a region where the magnetic field gradient—and thus the propulsive force—is close to zero. To address this, researchers developed coils with non-uniform winding densities, such as winding more layers of wire at the ends of the coil than in the middle. This shapes the magnetic field to create a steeper gradient where it is most needed, maximizing the force applied to the projectile and minimizing the inefficient "coasting" time.

- Permanent Magnet Projectiles: Another major step was to replace the passive ferromagnetic slug with an active projectile, specifically a high-strength permanent magnet. The intrinsic magnetic field of a permanent magnet interacts much more powerfully with the stator field than a simple induced field, leading to a dramatic increase in the available propulsive force and a corresponding improvement in velocity and efficiency.

- Bipolar Current Pulses: The most sophisticated optimization strategy involves manipulating the field in time as well as space. By incorporating an H-bridge circuit into the power supply, the direction of the current in the coil can be rapidly reversed. In such a system, the projectile (typically a permanent magnet) is first attracted toward the center of the coil. As it reaches the center, the control system reverses the current's polarity. The now-reversed magnetic field exerts a strong repulsive force, pushing the projectile out of the coil. This "push-pull" approach provides continuous acceleration throughout the projectile's transit through the coil and actively cancels the suck-back effect, leading to the highest reported gains in both velocity and efficiency.

- Optimizing Initial Position: On a more fundamental level, it has been shown that the initial starting position of the projectile relative to the first coil is a critical parameter. Even small adjustments to this position can significantly alter the initial magnetic flux linkage, resulting in substantial changes to the final muzzle velocity and efficiency.

Applications and Future Directions

The unique characteristics of coilgun technology—contactless acceleration, controllable thrust, and high potential velocity—make it a subject of interest for a diverse range of applications, spanning from military systems and space exploration to fundamental scientific research. The underlying physical principle of acceleration via a magnetic field gradient has proven to be remarkably scalable, applicable to systems designed to manipulate everything from individual atoms to multi-kilogram payloads.

Military and Defense Systems

Electromagnetic launcher technology is considered a strong candidate for future military weapon systems, offering capabilities beyond those of conventional chemical propellants. Potential applications include:

- Long-Range Fire Support: High-speed, multi-stage coilguns could be developed for long-range tactical and strategic bombardment, capable of launching projectiles over hundreds of kilometers.

- Tactical Mortars: The low acoustic and thermal signature of coilguns makes them particularly attractive for tactical mortar systems. A "silent" mortar would be ideal for covert operations or use in urban environments where minimizing collateral effects and avoiding detection are paramount.

- Smart Projectile Launch: Unlike the violent and uncontrolled explosion in a conventional gun, the acceleration profile in a coilgun can be precisely tailored by controlling the timing and magnitude of the current pulses. This "soft launch" capability is a significant advantage for launching projectiles containing sensitive electronic components, such as guided munitions or reconnaissance sensors.

Space Launch and Hypervelocity Research

Perhaps the most ambitious application proposed for coilgun technology is its use as a ground-based space launch system.

- Direct-to-Orbit Launch: A very large, multi-kilometer-long coilgun could potentially accelerate payloads to orbital velocity (approximately 7-8 km/s), eliminating the need for a first-stage rocket booster. This could dramatically reduce the cost and complexity of launching small to medium-sized payloads, such as nanosatellites, into Low Earth Orbit (LEO).

- Launch Assist: A more near-term concept is to use a coilgun to provide the initial launch velocity (e.g., 4-6 km/s), after which a small upper-stage rocket would ignite to perform the final orbital insertion. This would still significantly reduce the amount of propellant needed for a launch.

- Other Space Applications: Beyond satellite deployment, proposed space-based applications include launching supplies and fuel to space stations, launching probes to explore near-earth asteroids, and even launching sealed canisters of nuclear waste into deep space or onto the Moon for permanent disposal.

- Challenges: A major hurdle for this application is the extreme acceleration the payload would have to endure, on the order of thousands of times the force of gravity (gees). Any satellite or payload launched in this manner would need to be specifically designed and "hardened" to survive these immense forces.

Scientific Instrumentation: The Atomic Coilgun

The scalability of the coilgun principle is most strikingly demonstrated in its application at the atomic level. The "atomic coilgun" is a specialized scientific instrument that uses the same physical principles as a macroscopic coilgun, but for the opposite purpose: to decelerate and trap beams of atoms and molecules.

- Operating Principle: This device uses a series of pulsed magnetic coils to exert a force on paramagnetic atoms or molecules via the Zeeman effect. As a "low-field-seeking" atom (one whose potential energy increases with the magnetic field) enters a coil, its kinetic energy is converted into potential energy, causing it to slow down. By precisely switching off the magnetic field when the atom reaches the center of the coil, this potential energy is not converted back into kinetic energy, and the atom leaves the coil with a lower velocity.

- Applications in Physics: By repeating this process over many stages, a supersonic beam of atoms can be slowed to a complete stop and held in a magnetic trap. This technique is a vital tool in atomic physics, enabling experiments that require ultra-cold, trapped atoms. These experiments are used to conduct high-precision spectroscopy, test fundamental symmetries of nature, and study exotic states of matter like Bose-Einstein condensates.

The existence of applications ranging from launching 100 kg satellites to trapping single atoms reveals the profound versatility of the coilgun's core concept. It is not merely a single device but the practical implementation of a fundamental physical interaction—force generation in a magnetic field gradient—that can be engineered across immense scales for vastly different scientific and technological goals. This suggests that the engineering knowledge and simulation tools developed for one application, such as a military weapon, could have direct and valuable relevance to a seemingly unrelated field, like quantum physics, highlighting the broad, interdisciplinary importance of continued research into electromagnetic launch systems.