A pump is an energy-converting machine used to transfer fluids (liquids or gases) from one point to another. Pumps typically operate by converting mechanical energy into hydraulic energy, creating a pressure difference that drives the fluid in the desired direction. Today, pump systems are widely used in domestic water supply, industrial production lines, petrochemical plants, aerospace, and healthcare sectors.

Historical Development

The history of pumps dates back to ancient times. One of the earliest known types is the Archimedean screw, developed by Archimedes in the 3rd century BC. During the Industrial Revolution, the development of steam-powered mechanical pumps laid the foundation for modern pump technology. Today, various types of pumps, primarily powered by electric motors, are in widespread use.

Working Principle

Pumps are generally classified into two main groups: dynamic pumps and positive displacement pumps.

- Dynamic (kinetic) pumps continuously impart velocity (kinetic energy) to the fluid. The most common example is the centrifugal pump, where a rotating impeller applies centrifugal force to the fluid, directing it through a volute casing to the discharge line (Stepanoff, 1957).

- Positive displacement pumps operate by compressing and displacing a fixed volume of fluid. This category includes piston pumps, gear pumps, diaphragm pumps, and screw pumps. These types are typically used in applications requiring low flow rates and high pressure (Esposito, 2009).

Types of Pumps

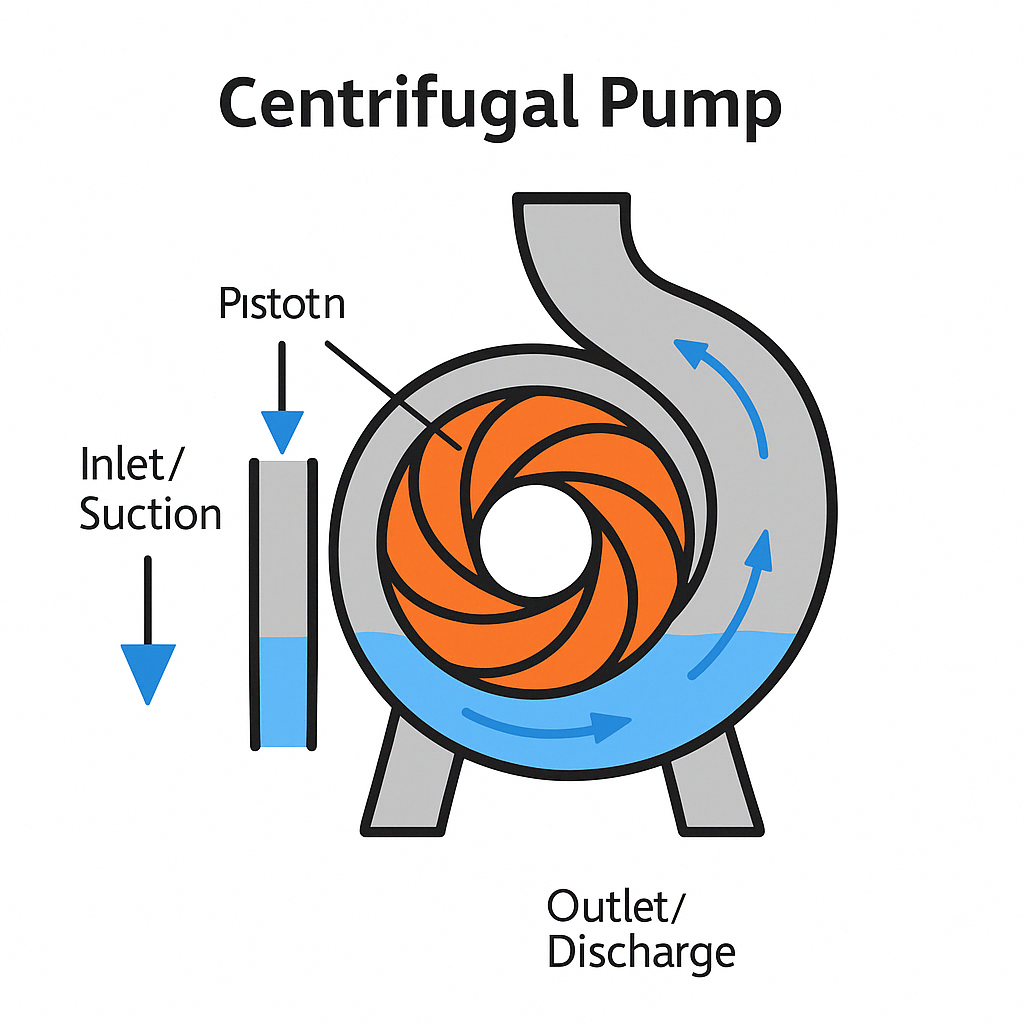

Centrifugal Pump (Generated with the assistance of artificial intelligence)

Centrifugal Pump

A centrifugal pump imparts kinetic energy to the fluid through a rotating impeller. It is generally suitable for high flow rate and low-viscosity fluids. Due to its simple structure and low maintenance requirements, it is widely used (Karassik et al., 2007).

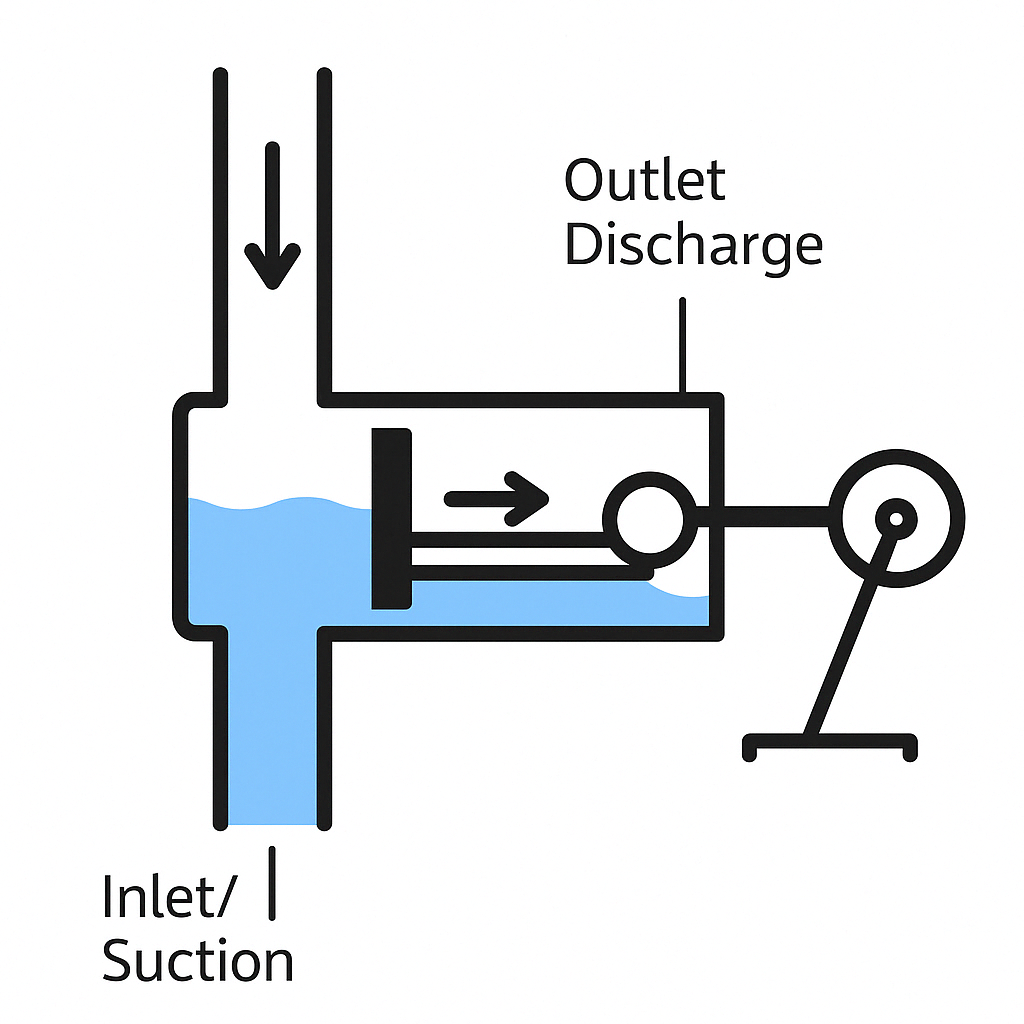

Piston Pump (Generated with the assistance of artificial intelligence)

Piston Pump

A piston pump transports fluid through the reciprocating motion of a piston. It is used in high-pressure applications and is preferred in systems where leak-free operation is essential.

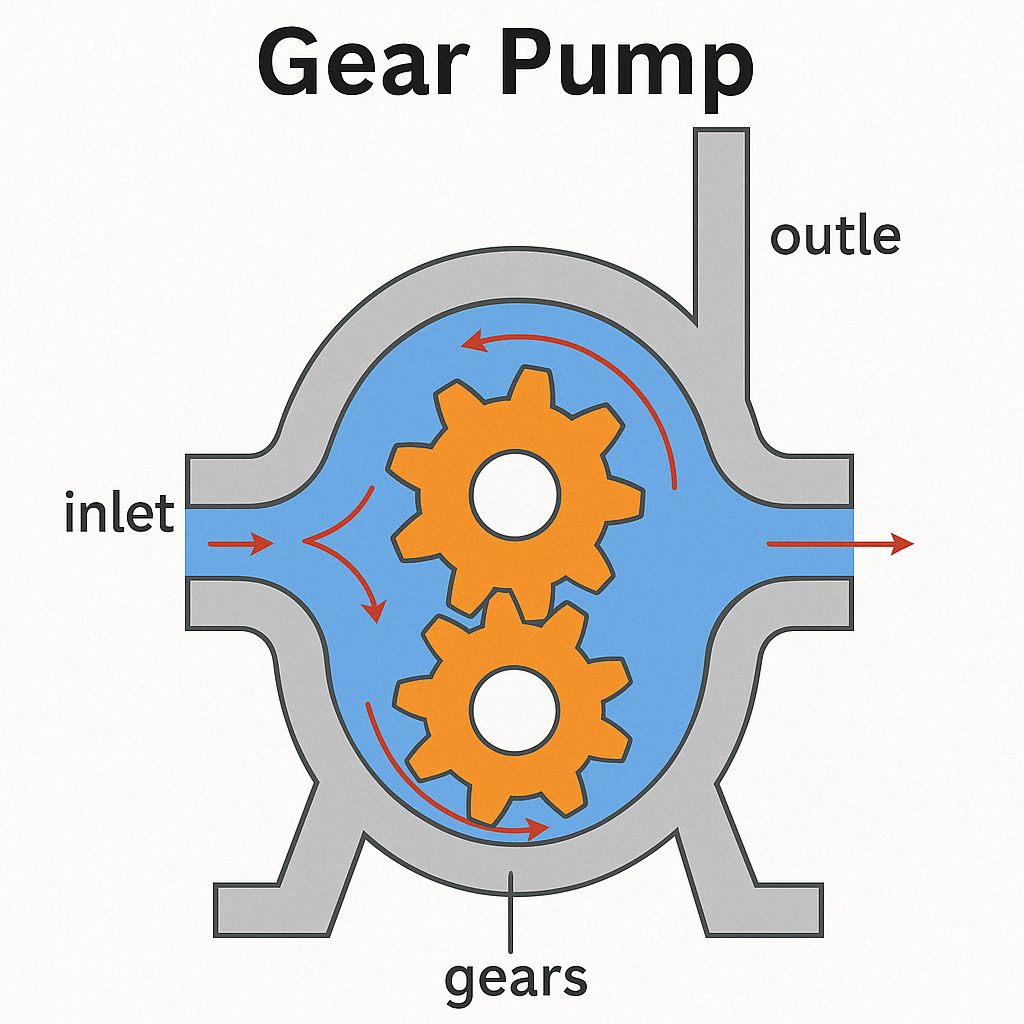

Gear Pump (Generated with the assistance of artificial intelligence)

Gear Pump

A gear pump moves fluid by means of two rotating intermeshing gears. It is ideal for viscous (thick) fluids and is commonly used in lubrication and hydraulic systems.

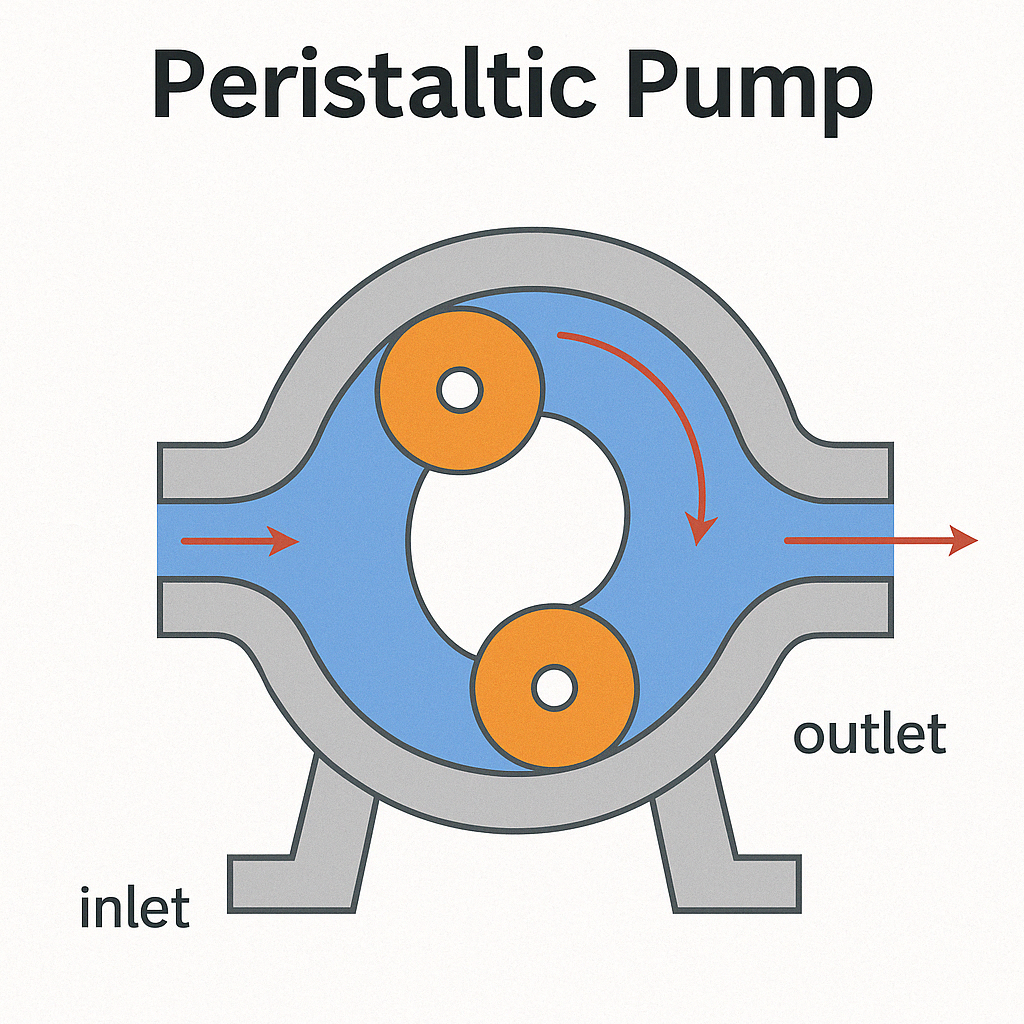

Peristaltic Pump (Generated with the assistance of artificial intelligence)

Peristaltic Pump

In peristaltic pumps, fluid is displaced by external compression applied along a flexible hose. Since the fluid only contacts the hose, it is particularly suitable for hygienic applications.

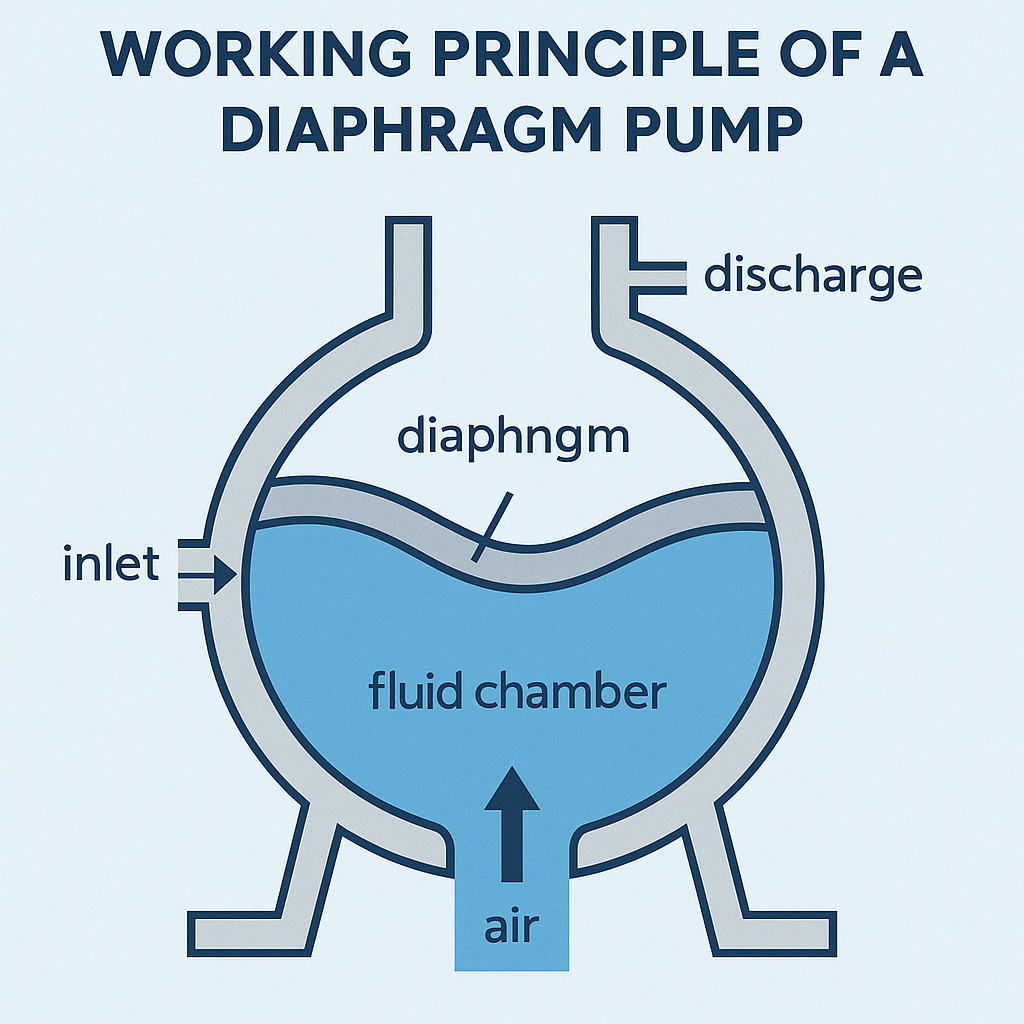

Diaphragm Pump (Generated with the assistance of artificial intelligence)

Diaphragm Pump

Diaphragm pumps operate by the reciprocating motion of a flexible diaphragm, which draws in and expels fluid. The diaphragm is usually actuated by compressed air or a mechanical linkage. When the diaphragm retracts, the suction valve opens and fluid enters the chamber; when it advances, the discharge valve opens and the fluid is expelled. Its leak-proof structure makes it reliable for transferring chemical or corrosive fluids.

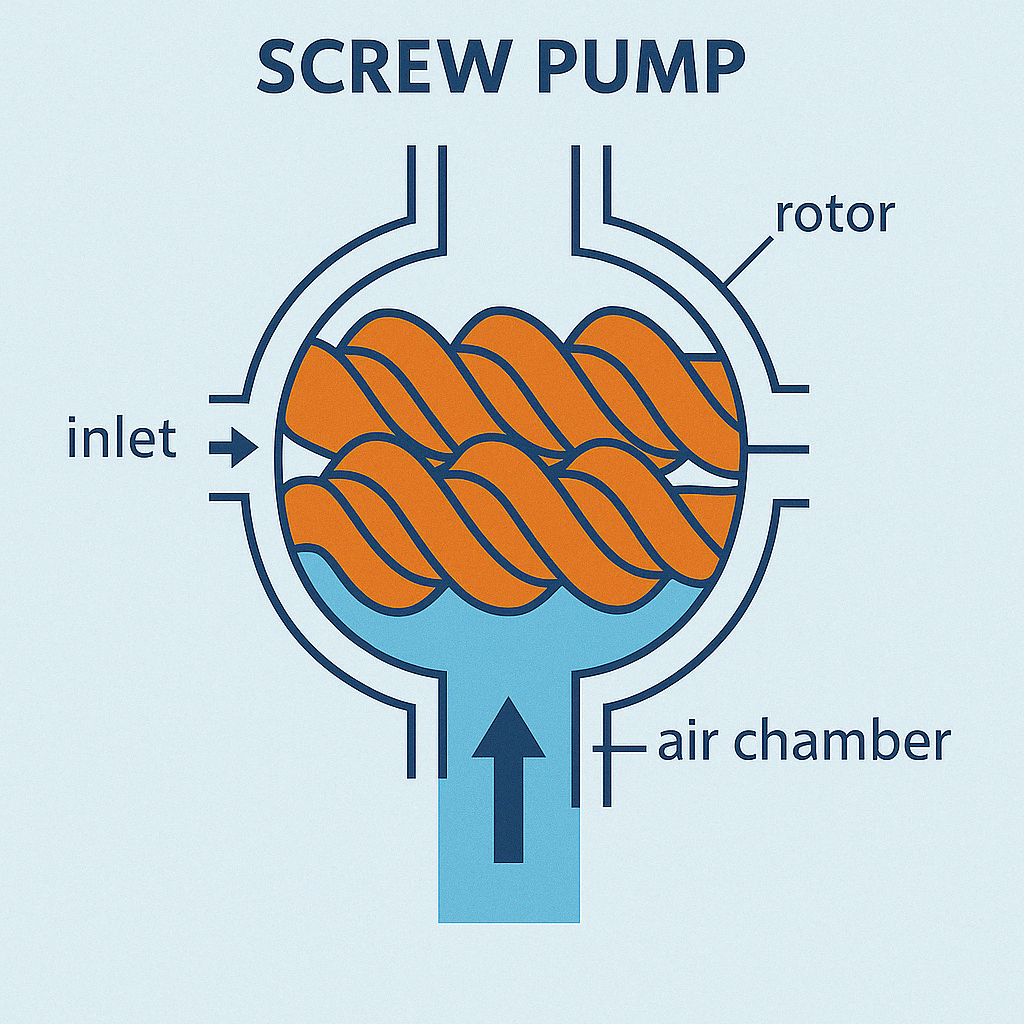

Screw Pump (Generated with the assistance of artificial intelligence)

Screw (Progressive Cavity) Pump

Screw pumps move fluid along the axis using intermeshing helical screws. The fluid is trapped in cavities between the threads and transported smoothly toward the outlet. This design ensures low pulsation and quiet operation. They are frequently used for handling viscous fluids and in precision industrial applications.

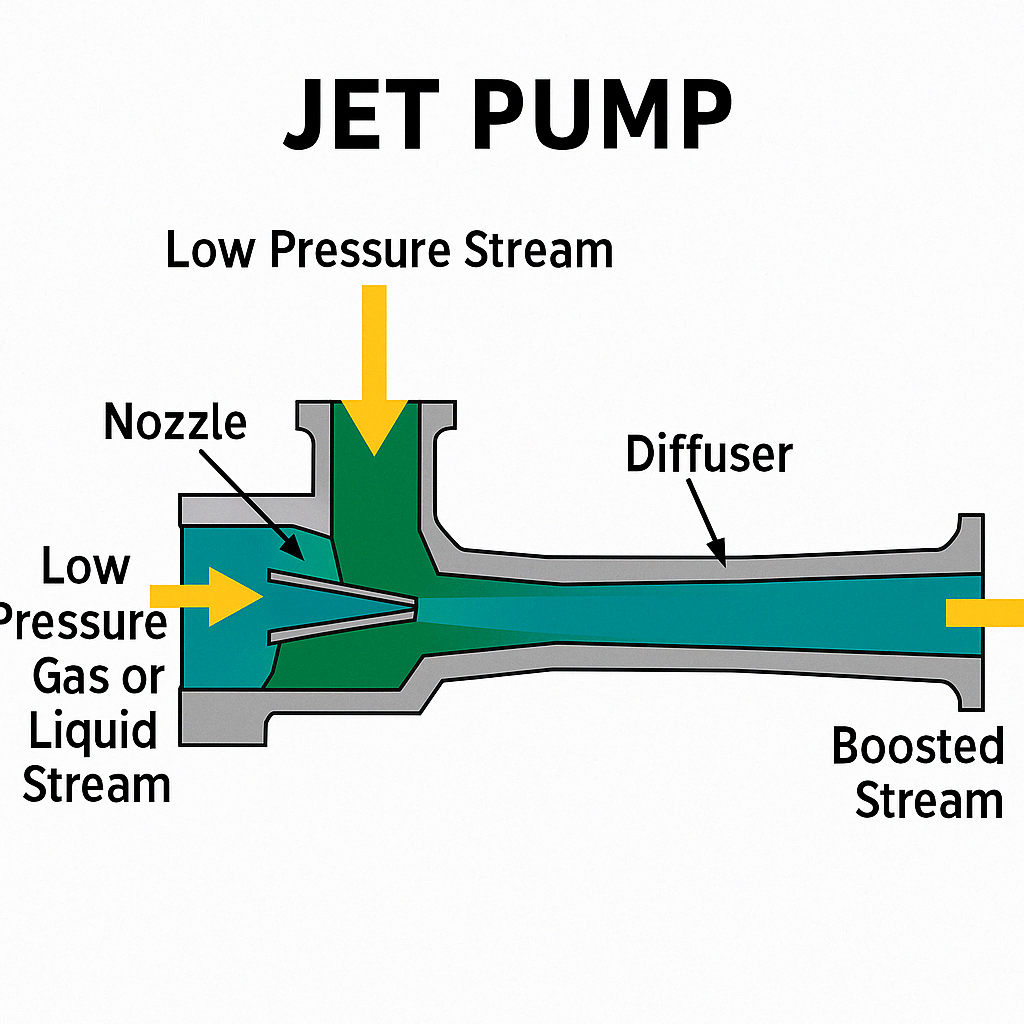

Jet Pump (Generated with the assistance of artificial intelligence)

Jet Pump

A jet pump is a type of pump that contains no moving mechanical parts and operates by utilizing the kinetic energy of a driving fluid to induce suction and convey another fluid. The principle involves passing a high-pressure fluid (usually water) through a narrow nozzle at high speed, which entrains a secondary fluid and creates a low-pressure zone. The entrained fluid is then mixed and directed through a diffuser to the outlet.

Performance Parameters

A pump's performance is evaluated using various engineering parameters:

- Flow rate (Q) – the volume of fluid transported per unit time (m³/s).

- Pressure difference (ΔP) – the difference in pressure between the inlet and the outlet (Pa).

- Efficiency (η) – indicates how much of the input energy is transferred to the fluid.

- NPSH (Net Positive Suction Head) – the minimum suction pressure required to prevent cavitation.

In pump design, the principles of energy conversion and fluid dynamics are considered in conjunction with thermodynamic and heat transfer analyses (Çengel and Ghajar, 2015).